The Power of Particle Counting

Particle count testing is a crucial technique used to determine the number and size distribution of particles in a fluid sample. It involves passing the sample through a specialized instrument, such as a particle counter, which detects and quantifies the particles based on their size or optical properties. Knowing the particle count can help find extensive applications in various industries, including oil analysis and hydraulic systems. By providing valuable insights into the level of contamination or wear debris in a fluid, particle counting plays a vital role in equipment health monitoring, preventive maintenance, and quality control, ensuring optimal performance and reliability.

Particlecounting is a key aspect to be considered in lube oil and hydraulic oil condition monitoring. It offers early problem detection, proactive maintenance planning, enhances equipment reliability, ensures contamination control, enables predictive maintenance, maintains compliance and quality, promotes safety, reduces costs, improves efficiency, and aids in root cause analysis. The foundation of a detailed particle count test ensures reliable, safe, and cost-effective maintenance practices in machinery systems.

How is particle count testing a valuable asset to your machinery?

- Early Detection of Equipment Issues: Particle count testing helps identify wear particles and contaminants in fluids early, allowing for timely maintenance and preventing equipment failures.

- Optimized Preventive Maintenance: Regular particle count analysis allows for better maintenance scheduling, reducing downtime and extending equipment lifespan.

- Improved Product Quality and Consistency: Ensures cleaner fluids in manufacturing, leading to higher product quality and consistency.

- Enhanced Process Efficiency and Cost Savings: Helps control contamination levels, improving process efficiency and avoiding costly breakdowns.

- Environmental Monitoring and Regulatory Compliance: Useful for assessing air and fluid cleanliness, ensuring compliance with environmental and safety regulations.

- Valuable Data for Research and Development: Particle behaviour analysis aids in research and development, leading to advancements in various fields.

- Increased Equipment Reliability and Lifespan: Maintaining fluid cleanliness through testing contributes to better equipment performance and longevity.

Exploring the methods of particle count testing

There are several methods used for particle count analysis, each employing different principles and techniques to determine the concentration and size distribution of particles in a fluid sample. The main types of methods used for a precise particle count test include:

- Optical Particle Counting (OPC): Uses light scattering to detect and count particles in a sample based on size and concentration.

- Coulter Counter: Utilizes electrical impedance to count and size particles passing through a small aperture.

- Gravimetric Analysis: Captures particles on a filter membrane, measuring weight change to determine concentration.

- Microscopic Particle Analysis: Involves manual counting and analysis of particles using microscopy.

- Ferrography: Separates particles based on their magnetic properties, used for wear analysis in lubricants.

- Flow Cytometry: Uses laser beams and light scattering to identify and count particles, commonly used in medical research.

- Coulter Multisizer: Measures and counts particles over a wide size range using electrical impedance.

Each method has specific advantages and limitations, and selection depends on particle size range, accuracy, sample type, and required detail.

The National Aerospace Standard for particle count testing

The National Aerospace Standard (NAS) in terms of particle count refers to a widely recognized and accepted classification system used to assess and monitor the cleanliness levels of fluids, particularly in aerospace and critical industries. This standard establishes specific limits for particle counts of varying sizes in fluids like hydraulic fluids, lubricating oils, and fuels. The NAS system categorizes particles into different size ranges, often referred to as NAS classes, such as NAS 1638 which correspond to specific allowable particle counts for each size range. These standards provide a uniform method for measuring and reporting the cleanliness of fluids, enabling industries to maintain the desired quality of fluids used in critical applications.

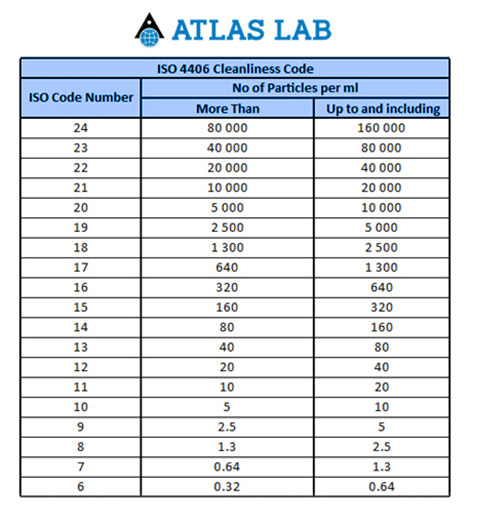

In recent times, ISO 4406 has largely taken the lead over NAS 1638. Both NAS 1638 and ISO 4406 are concerned with the methodologies for quantifying the levels of solid contaminants or particle counts present in a fluid.

NAS 1638 categorizes particle counts into five distinct size ranges:

- 5 to 15 microns per 100 millilitres (mL)

- 15 to 25 microns per 100 mL

- 25 to 50 microns per 100 mL

- 50 to 100 microns per 100 mL

- Above 100 microns per 100 mL

In contrast, ISO 4406:1999 divides particle counts into three size ranges:

- Particles larger than 4 microns per 1 mL

- Particles larger than 6 microns per 1 mL

- Particles larger than 14 microns per 1 mL

Atlas Lab’s Leading-edge Particle Count Testing Service

As industry leaders, Atlas Lab offers a comprehensive suite of solutions that cater to all your particle count testing needs. Our cutting-edge PAMAS SBSS particle counter instrument is an advanced particle count machine that ensures unmatched accuracy and reliability, providing precise insights into fluid cleanliness and equipment health. Whether it's early detection of contaminants, optimized preventive maintenance, or compliance with regulatory standards, Atlas Lab’s advanced technology guarantees exceptional results. Trust in our expertise to elevate your operations, enhance product quality, and ensure the longevity of your valuable assets. Experience the pinnacle of particle count testing services with Atlas Lab, your trusted partner for excellence and innovation.