Discover the Versatile Wonders of Coconut Oil: A Brief Introduction

In recent times, the demand for coconut and specifically coconut oil has skyrocketed due to its widely claimed health advantages. Coconut oil is reputed to aid in the reduction of abdominal fat, suppression of appetite, enhancement of the immune system, prevention of heart disease, and prevention of dementia and Alzheimer's disease. The oil is derived from the pressing of either fresh coconut meat or dried coconut meat known as copra. Fresh meat is utilized in the production of virgin coconut oil, while copra is typically used in refined coconut oil. Unlike olive oil, the terms "virgin" and "extra virgin" are not regulated when it comes to coconut oil.

Coconut oil is composed entirely of fat, with approximately 80-90% of it being saturated fat.The most prevalent among them is lauric acid, accounting for 47% of the composition. Additionally, myristic and palmitic acids are present in smaller quantities. Trace amounts of monounsaturated and polyunsaturated fats can also be found in coconut oil.It's worth noting that coconut oil does not contain cholesterol, fibre, and contains small amounts of essential vitamins, minerals, and plant sterols.

Coconut oil possesses a distinctive flavour that sets it apart, making it most suitable for occasional usage as an alternative to other oils in baking and cooking. When incorporated within a balanced and nutritious diet, it can add a touch of variety and flavour to culinary preparations.

The growing demand for coconut oil has highlighted the importance of coconut oil testing, making it a mandate for both, small and large refineries to get their oil tested regularly.

Unveiling the Perils of Adulterated Coconut Oil: Common Problems and Concerns

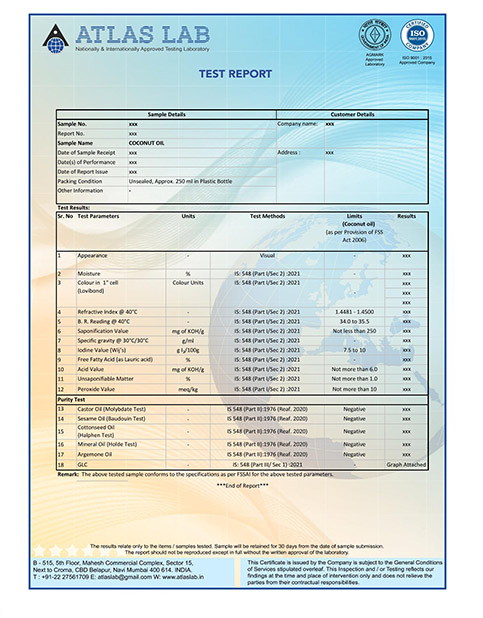

The coconut oil test report includes information about the important parameters that are analyzedduring the testing process. These commonly include:

Palm Kernel Oil:

Coconut oil and palm kernel oil share certain similarities in their chemical composition and physical properties. This similarity in texture and consistency makes palm kernel oil a convenient choice for adulterating coconut oil. Palm kernel oil is generally less expensive compared to coconut oil. Adulterating coconut oil with palm kernel oil allows unscrupulous suppliers or manufacturers to lower their production costs while still maintaining a similar appearance and texture.

Argemone Oil:

Argemone, a weed native to Mexico, contains toxic alkaloids and yields an inedible oil. Surprisingly, despite its inherent dangers, numerous oil brands choose to employ it for adulteration purposes with edible coconut oil.

Paraffin:

Paraffin, a substance formerly utilized by numerous reputable companies, continues to be unlawfully employed by unscrupulous merchants as a substitute or adulterant for coconut oil, often blending it with palm oil, posing serious health threats.

Increase Oil by Volume:

To manipulate the volume of oil being sold in India, an artificial chemical is introduced, causing the oil to expand from 1 liter to 1.1 liters. This practice is adopted due to the prevalent practice of selling oils based on volume rather than weight in the country.

Fungus:

Fungal growth, specifically moulds, poses significant challenges for copra (dried coconut). When coconut does not undergo proper drying, it retains moisture, leading to the development of fungal growth.In modern times, inexpensive methods like bleaching, filtering, and pasteurization have emerged as alternatives. As a result, mills now accept these low-quality coconuts at extremely low prices and mix them with other nuts.

Hexane:

Hexane, a commonly utilized solvent is used to extract the maximum amount of oil from coconuts, which is toxic to humans.

Bleach:

Over time, the accumulation of aged oil within the machinery turns rancid, and when it mixes with fresh oil, it contaminates the entire batch. This is when incorporating bleaching, filtering, and chemical preservatives becomes a part of the process, which tampers with the quality of edible coconut oil.

Deodorize:

This practice is employed once more due to the fact that after thorough filtration, the oil loses its inherent qualities and becomes devoid of any distinct characteristics. It essentially becomes a bland substance, lacking aroma and flavor. Therefore, the solution lies in introducing approved chemical substitutes to infuse the oil with the desired sensory attributes.

Chips/Paring Oil:

During the production of Desiccated Coconut Powder, the black skin of the coconut is removed, and only the kernel is powdered and dried to create the final product. This skin, known as a byproduct, is dried and sold at approximately 65% of the cost of copra. While it contains oil like copra, the quality of the oil is inferior. Many manufacturers blend these coconut chips with copra to extract the oil.

Second grade oil:

High-quality copra exhibits a white colour and a delightful aroma, while deteriorated copra tends to be darker in colour with an unpleasant smell. Inferior-grade copra is typically sold at a lower price compared to its superior counterpart. It is possible to blend this lower-quality copra with good-quality copra during the oil extraction process, resulting in an oil thatwill quickly degrade over time.

Refined Coconut Oil:

Refining with a base removes excessive Free Fatty Acids (FFA) from Coconut Oil, sourced from lower-grade copra or solvent-extracted from coconut oil cake. The refined oil meets safety standards, but loses its original taste, aroma, and quality, depriving consumers of desirable attributes.

Critical Test Parameters for Coconut Oil

The following are the coconut oil testing parameters that should be evaluated for a smooth coconut oil analysis:

- Free Fatty Acid (FFA) Content: Determines the concentration of FFA, which indicates the freshness and quality of the oil.

- Moisture Content: Measures the amount of water present in the oil, ensuring it falls within acceptable limits to prevent spoilage

- Peroxide Value (PV): Indicates the extent of oxidation in the oil, serving as an indicator of its freshness and susceptibility to rancidity.

- Iodine Value (IV): Measures the oil's unsaturation level and helps assess its stability and potential for oxidation.

- Acid Value (AV): Indicates the amount of acid present in the oil, reflecting its overall quality and purity.

- Saponification Value (SV): Determines the average molecular weight of the fatty acids in the oil, providing insights into its composition.

- Specific Gravity: Measures the density of the oil relative to water, aiding in the identification and characterization of the product.

- Smoke Point: Indicates the temperature at which the oil starts to smoke and break down, affecting its suitability for different cooking applications.

- Colour: Evaluates the visual appearance of the oil, ensuring it falls within acceptable color ranges.

Ensuring Purity and Quality: The Vitality and Rewards of Coconut Oil Testing

Coconut oil testing refers to the process of analyzing coconut oil samples to assess their quality, purity, and composition. This coconut oil test report plays a crucial role in ensuring the safety and authenticity of coconut oil products. Here are some benefits and importance of coconut oil testing:

- Quality assurance:Testing helps ensure that coconut oil meets the required quality standards. It can identify contaminants, such as heavy metals, pesticides, or microbial contaminants, that may be harmful to human health.

- Authenticity verification: Testing can verify the authenticity of coconut oil by checking for adulteration or dilution with other oils.

- Nutritional profiling: Coconut oil testing can determine the nutritional composition of the oil, including its fatty acid profile, vitamins, and antioxidant content.

- Shelf-life assessment: Testing can evaluate the stability and shelf-life of coconut oil. It helps determine the oil's resistance to oxidation and rancidity, ensuring that it remains fresh and safe for consumption over time.

- Regulatory compliance: Coconut oil testing is often required to comply with regulatory standards and labeling requirements set by government authorities. By conducting these tests, manufacturers can ensure that their products meet the legal requirements and provide accurate information to consumers.

- Research and development: Testing can support research and development efforts in the coconut oil industry. It provides valuable data that can be used to improve production processes, develop new products, and enhance the overall quality of coconut oil.

- Consumer confidence: Through testing, coconut oil manufacturers can demonstrate their commitment to quality, safety, and transparency. This instills confidence in consumers, as they can trust that their coconut oil has undergone rigorous testing to meet industry standards.

Atlas Lab: Your Reliable Partner for Comprehensive Coconut Oil Testing Solutions

Atlas Lab is one of the most well-acclaimed coconut oil testing lab that offers an advanced and all-encompassing program for testing and analyzing edible oils. Through the meticulous examination of edible oil samples, we assess various aspects including their quality, confirm their adherence to quality standards, evaluate blending techniques, ensure the accurate blend is provided, prevent contamination, and validate compliance with national and international technical and environmental standards.

We are a coconut oil testing lab that conducts a range of tests to evaluate the quality and characteristics of edible oils. These tests, conducted in accordance with FSSAI, PFA, and BIS standards, include:

Gas Liquid Chromatography (GLC): This test is employed to estimate various components of the edible oil, such as fatty acids, including saturated, unsaturated, monounsaturated, and polyunsaturated fatty acids. It also helps identify trans fatty acids and determine the levels of Omega-3, Omega-6, and Omega-9 fatty acids.

Shelf-Life Evaluation: Edible oils, particularly those rich in polyunsaturated fatty acids, are prone to oxidation when exposed to oxygen, heat, and light. This oxidation process leads to the formation of undesirable oxidation products like peroxides and hydroperoxides. By assessing the levels of these compounds, Atlas Lab determines the shelf life or stability of the edible oil.

These tests provide valuable insights into the composition, quality, and shelf life of the tested edible oils, ensuring compliance with relevant standards and helping businesses and consumers make informed decisions.