Pyrolysis Oil Testing

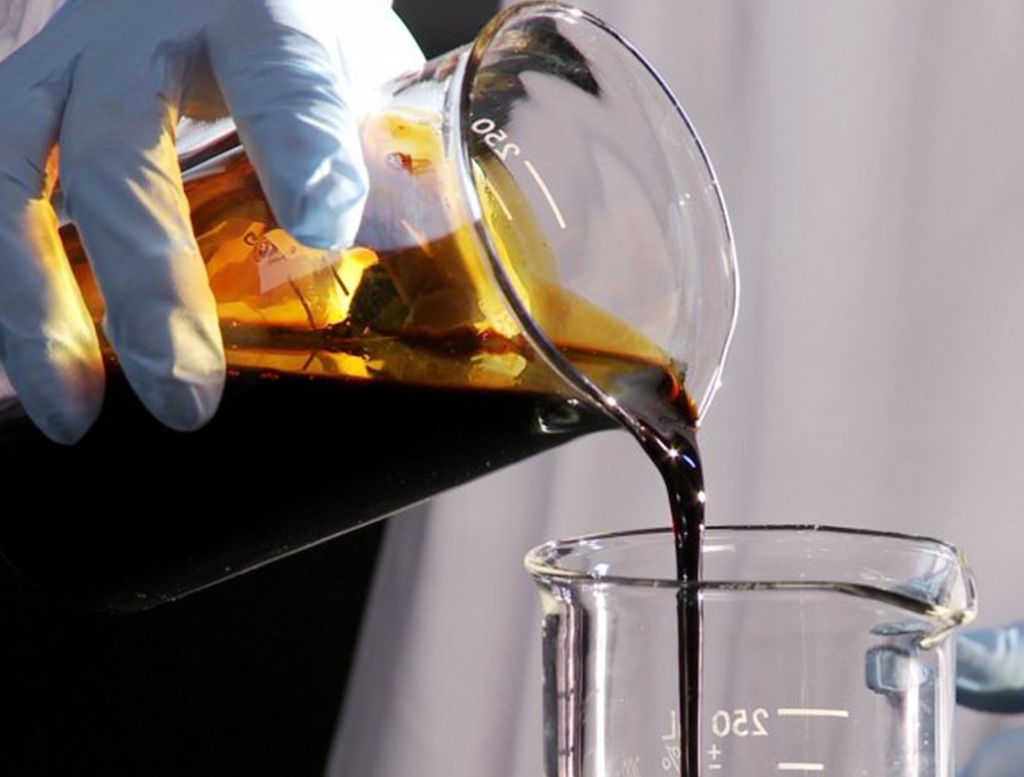

Pyrolysis oil, also known as plastic pyrolysis oil or waste-derived oil, is produced through the thermal decomposition of waste materials such as plastics, tyres, biomass, and rubber in the absence of oxygen. As industries increasingly adopt circular economy and waste-to-energy solutions, pyrolysis oil is being used as an alternative fuel or feedstock in industrial burners, boilers, furnaces, and refineries. However, due to its variable composition and potential contaminants, comprehensive pyrolysis oil testing is essential to ensure safe use, performance reliability, and regulatory compliance.

Importance of Pyrolysis Oil Testing

Pyrolysis oil can vary significantly depending on feedstock, process conditions, and storage. It may contain water, sediments, high sulphur, chlorine, metals, or unstable compounds that can cause corrosion, fouling, emissions issues, and equipment damage if left unchecked. Routine pyrolysis oil testing helps identify these risks early, enabling users to assess suitability for combustion, blending, or further processing while preventing operational failures and environmental non-compliance.

Benefits of Pyrolysis Oil Testing and Analysis

- Verifies fuel quality and consistency

- Detects contaminants such as water, sediments, sulphur, chlorine, and metals

- Prevents corrosion, fouling, and equipment damage

- Supports safe combustion and process compatibility

- Assists in regulatory and environmental compliance

- Enables blending, upgrading, or refining decisions

Atlas Lab provides comprehensive pyrolysis oil testing and analysis services for waste-to-energy operators, recyclers, industrial users, and fuel traders. As a NABL-accredited and ISO/IEC 17025-certified laboratory, Atlas Lab performs testing in accordance with ASTM, ISO, IP, and relevant regulatory guidelines, delivering accurate results with fast turnaround times.

Key Pyrolysis Oil Tests Performed

- Density and specific gravity

- Kinematic viscosity

- Flash point

- Water content (Karl Fischer)

- Total sulphur content

- Carbon residue

- Ash content

- Calorific value (GCV / NCV)

- Sediment and particulate contamination

- Elemental analysis (C, H, N, S)

- Chlorine content (where applicable)

Applications of Pyrolysis Oil Testing

Pyrolysis oil testing supports:

- Waste-to-energy and plastic recycling plants

- Industrial boilers, furnaces, and burners

- Cement and power plants using alternative fuels

- Fuel blending and upgrading operations

- Refinery and petrochemical feedstock assessment

- Environmental and regulatory compliance

With advanced analytical instrumentation, experienced fuel specialists, and rapid reporting, Atlas Lab is a trusted partner for pyrolysis oil testing and analysis in India and globally. Our testing helps clients ensure fuel safety, optimise performance, protect equipment, and make informed decisions when using waste-derived fuels.

Reach Out

Contact Atlas Lab today for professional pyrolysis oil testing and analysis services and ensure your alternative fuels meet performance, safety, and compliance requirements.

Phone :+91 9324631646

WhatsApp : +91 9324631646

Email : contact@atlaslab.in