Mastering Engine Oil Analysis: A Comprehensive Guide to Evaluating Oil Quality and Detecting Potential Issues

Engine oil is often referred to as the lifeblood of the machinery and engines, and for good reason. It plays a critical role in ensuring the smooth and efficient operation of an engine, protecting vital components, and extending its longevity.

Engine oil acts as a lubricant, reducing friction between moving parts, preventing excessive wear and tear, and dissipating heat generated by the engine's internal combustion process.

Without proper lubrication, the engine's performance could suffer, leading to decreased efficiency, increased fuel consumption, and even catastrophic failure.

Moreover, engine oil is not a static component within your vehicle. It undergoes continuous changes as it circulates through the engine, collecting contaminants, breaking down due to heat and chemical reactions, and gradually losing its effectiveness. It is recommended to learn how to check engine oil quality to ensure optimal performance and longevity of your machinery.

The Evolution of Engine Oils: Tracing the Path of Lubrication Through the Ages

The story of engine oils dates back centuries, tracing its roots to ancient civilizations that recognized the importance of lubrication for machinery. While the early lubricants used were far from the sophisticated oils we have today, they laid the foundation for the development of the engine oils that power our modern vehicles.

Ancient civilizations, such as the Egyptians and Mesopotamians, used various substances to reduce friction between moving parts. Animal fats, vegetable oils, and even liquids like water and wine were employed to lubricate axles and cart wheels.

The industrial revolution in the 18th and 19th centuries marked a significant turning point in the history of engine oils. With the rise of steam power and the invention of steam engines, the need for more reliable and efficient lubricants became apparent. Mineral oils, derived from petroleum, gained prominence as a lubricant during this era.

As automotive technology advanced in the early 20th century, the demand for specialized engine oils grew. The introduction of the internal combustion engine brought about new challenges, such as increased heat generation, higher operating speeds, and the accumulation of harmful by-products. Engineers and scientists responded by formulating oils with enhanced heat resistance, better detergent properties, and anti-wear additives to combat these issues.

Today, engine oils have reached unprecedented levels of sophistication. They are meticulously formulated to meet the precise requirements of modern engines, providing optimal protection, lubrication, and cleanliness.

The history of engine oils is a testament to human ingenuity and the relentless pursuit of efficiency and reliability. From the simple lubricants of ancient times to the technologically advanced formulations of today, engine oils have played a vital role in the development and progress of transportation and machinery.

Engine oils play a crucial role in industries worldwide due to several key reasons:

Lubrication: Lubrication: One of the primary functions of engine oils is to lubricate the moving parts within machinery and engines. They reduce friction and wear between components, minimizing heat generation and extending the lifespan of critical equipment.

Heat Dissipation: Industries often involve heavy machinery and engines that generate significant heat during operation. Engine oils act as effective heat transfer mediums, absorbing and dissipating heat from engine components.

Contamination Control: Industrial environments can be harsh, exposing machinery to various contaminants, such as water, dust, dirt, metal particles, and combustion by-products. Engine oils incorporate additives that act as detergents, dispersants, and antioxidants, reducing the accumulation of harmful deposits.

Seal Conditioning: Engine oils contribute to the proper functioning of seals and gaskets within machinery. They help keep seals supple and prevent them from drying out, cracking, or becoming brittle.

Performance Optimization: Industries rely on machinery and engines to deliver consistent performance and productivity. Engine oils are specifically formulated to meet the requirements of different applications, providing the necessary viscosity, additives, and performance characteristics.

Key Considerations for Selecting Engine Oil: Exploring Essential Properties

Discover the fool proof criteria on how to check if engine oil is good or badand ensuring that your vehicle operates at its best by checking the following parameters:

Kinematic Viscosity

Kinematic viscosity stands out as a significant parameter in characterizing fluid behaviour and predicting its performance under different conditions. Unlike dynamic viscosity, which directly quantifies the resistance to flow, kinematic viscosity focuses on the fluid's internal friction per unit density. By considering the ratio of viscous forces to inertial forces, kinematic viscosity provides insights into the fluid's ability to flow and its response to external forces.

Measurement of kinematic viscosity is typically performed using a viscometer, a device specifically designed to determine the flow characteristics of fluids. Understanding kinematic viscosity is essential in various industrial applications. In automotive engineering, it plays a vital role in determining the efficiency and performance of lubricants. In the petroleum industry, kinematic viscosity is critical for the production, transportation, and processing of crude oil.

Kinematic viscosity also finds applications in materials science, manufacturing processes, and quality control.

Flash Point (COC)

Considering the flash point when selecting an engine oil is essential for ensuring safety, as it indicates the temperature at which the oil's vapours can ignite; choosing an oil with an appropriate flash point reduces the risk of fire accidents. Additionally, the flash point helps determine the oil's suitability for specific applications and operating conditions, ensuring optimal performance and thermal stability. By selecting an engine oil with a suitable flash point, you minimize the risk of fire hazards, maintain lubrication efficiency, and enhance the longevity of your engine.

Pour Point

Pour Point is an important consideration when selecting an engine oil because it determines the oil's ability to flow at low temperatures. The pour point represents the lowest temperature at which the oil can still flow, without being too thick or solidified. Choosing an engine oil with a low pour point ensures that it remains fluid even in cold weather conditions, allowing for easy engine startup, effective lubrication, and optimal protection against wear. By selecting an oil with a suitable pour point, you reduce the risk of damage due to inadequate lubrication in cold environments.

Total Base Number

The Total Base Number (TBN) is an essential factor to consider when selecting an engine oil due to its ability to neutralize acidic by-products that form during engine operation. The TBN represents the oil's alkaline reserve, indicating its capacity to counteract acidic contaminants and prevent corrosive damage to engine components. Over time, as the engine oil ages, it becomes increasingly acidic due to the combustion process and oil degradation. By choosing an engine oil with a higher TBN, you ensure that it can effectively neutralize acids and maintain the optimal pH balance within the engine, preventing corrosion, extending the engine's life, and preserving its overall performance.

Viscosity Index

Checking the Viscosity Index (VI) is important when selecting an engine oil because it provides valuable information about the oil's resistance to viscosity changes with temperature variations. The VI measures how much the viscosity of an oil changes with temperature, specifically its ability to maintain a stable viscosity across a range of operating temperatures. Engine oils with a higher VI exhibit minimal changes in viscosity, ensuring consistent lubrication performance and protection under both high and low-temperature conditions.

The Critical Impact of Engine Oil Quality on Machinery Performance and Reliability

The quality of engine oil is crucial for the optimum functioning of machinery. High-quality oil provides effective lubrication between moving parts, reducing friction and wear. It forms a protective barrier that extends the lifespan of critical components and ensures smooth operation. On the other hand, poor-quality oil can lead to increased friction, accelerated wear, and potential damage to machinery, compromising its performance and longevity.

Additionally, engine oil quality affects heat management and temperature control. High-quality oil efficiently dissipates heat generated during operation, preventing overheating and thermal breakdown. It maintains stable viscosity across a wide temperature range, ensuring consistent lubrication and preventing viscosity-related issues.

Additionally, engine oil quality affects heat management and temperature control. High-quality oil efficiently dissipates heat generated during operation, preventing overheating and thermal breakdown. It maintains stable viscosity across a wide temperature range, ensuring consistent lubrication and preventing viscosity-related issues.

Proper engine maintenance starts with knowing how to check engine oil. Discover the essential steps to ensure peak performance and longevity.

The Vital Importance of Engine Oil Testing: Ensuring Performance and Compliance through Atlas Lab's Stringent Standards

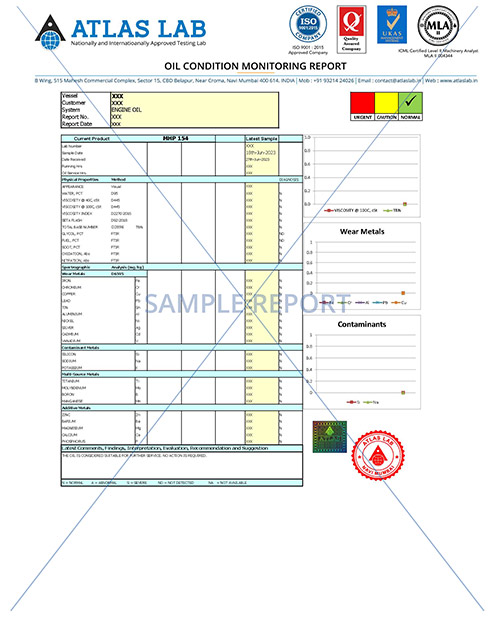

Atlas Lab offers a complete solution on how to check engine oil condition and delivers accurate, quick and cost-effective outcomes, on a global scale.

Similar to analysing blood samples in a laboratory, testing and analysing the engine oil can provide a comprehensive diagnosis of the engine's condition, including contamination levels and signs of wear and tear. Regular testing of engine oil samples allows for the early identification of potential problems, helping to avoid unnecessary downtime and keeping the engine in optimal condition.

At Atlas Lab, we offer a comprehensive and advanced engine oil testing and analysis service. Our testing procedures adhere to globally recognized standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

We conduct various tests on engine oil, including viscosity, water content, oxidation levels, PQ Index, Total Acid Number, Total Base Number, among others. Our team of experts in the field of testing and analysis, with over 40 years of combined experience, ensure precise and accurate results for your engine oil-related concerns.