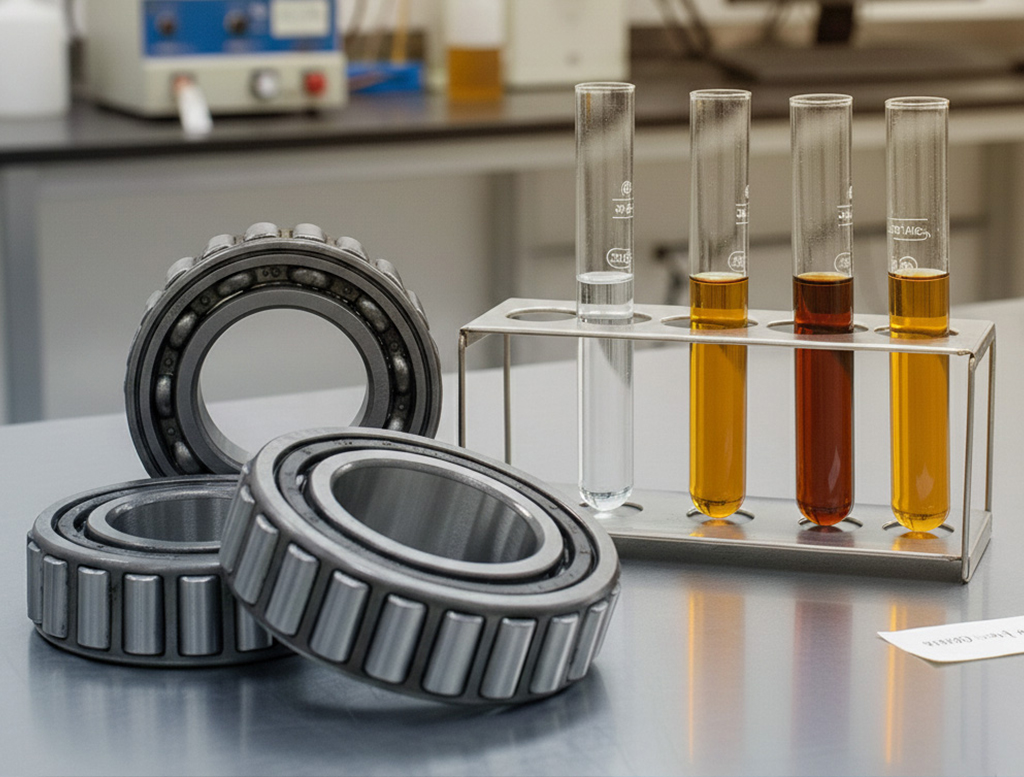

Bearing Oil Testing

Bearings are critical components in rotating machinery, enabling smooth motion while carrying heavy loads at high speeds. Found in equipment such as motors, gearboxes, turbines, pumps, compressors, conveyors, and industrial fans, bearings operate under constant mechanical stress. The performance and lifespan of bearings depend heavily on the condition of the lubricating oil or grease. Bearing oil testing is essential to monitor lubricant health, detect early signs of wear, and prevent unexpected bearing failures.

Importance of Bearing Oil Testing

Bearing lubricants are exposed to high loads, frictional heat, oxidation, and contamination from dust, moisture, and metal particles. Over time, lubricant degradation and contamination can lead to increased friction, overheating, and accelerated bearing wear. Routine bearing oil testing helps identify early warning signs such as metal wear debris, water ingress, additive depletion, and oil breakdown, allowing maintenance teams to take corrective action before costly breakdowns or equipment damage occur.

Benefits of Bearing Oil Testing

- Detects early-stage bearing wear and lubrication issues

- Identifies contamination from water, dust, and particulates

- Prevents overheating, seizure, and catastrophic bearing failure

- Extends bearing and lubricant service life

- Reduces unplanned downtime and maintenance costs

- Supports condition-based and predictive maintenance (CBM)

Atlas Lab provides comprehensive bearing oil testing and analysis services for a wide range of industries, including power generation, steel, cement, oil & gas, marine, automotive, mining, and manufacturing. As a NABL-accredited and ISO/IEC 17025-certified laboratory, Atlas Lab performs bearing oil testing in accordance with ASTM, ISO, and OEM-recommended standards, delivering accurate results with fast turnaround times.

Key Bearing Oil Tests Performed

- Viscosity and viscosity index

- Wear metal analysis (iron, copper, chromium, aluminium)

- Particle contamination and cleanliness (ISO 4406)

- Water content (Karl Fischer)

- Oxidation and thermal degradation

- Total Acid Number (TAN)

- Additive depletion monitoring

- Ferrography and wear particle analysis

With advanced analytical instrumentation, experienced lubrication specialists, and rapid reporting, Atlas Lab is a trusted partner for bearing oil testing in India and globally. Our testing provides actionable insights that help clients optimise lubrication practices, extend bearing life, and ensure reliable equipment performance.

Reach Out

Contact Atlas Lab today for professional bearing oil testing and analysis services and protect your rotating equipment with informed, data-driven maintenance decisions.

Phone :+91 9324631646

WhatsApp : +91 9324631646

Email : contact@atlaslab.in